Silicon Carbide: Leading the Transformation in Semiconductor Products with Advanced Power Gadget

Carbonized silicon (Silicon Carbide, SiC), as an agent of third-generation wide-bandgap semiconductor materials, has demonstrated tremendous application potential against the background of expanding international need for tidy energy and high-efficiency electronic tools. Silicon carbide is a compound made up of silicon (Si) and carbon (C), featuring either a hexagonal wurtzite or cubic zinc blend framework. It flaunts superior physical and chemical homes, including an extremely high break down electrical field stamina (roughly 10 times that of silicon), reduced on-resistance, high thermal conductivity (3.3 W/cm · K compared to silicon’s 1.5 W/cm · K), and high-temperature resistance (approximately above 600 ° C). These qualities permit SiC-based power devices to operate stably under higher voltage, frequency, and temperature level conditions, achieving extra reliable energy conversion while dramatically decreasing system dimension and weight. Especially, SiC MOSFETs, contrasted to standard silicon-based IGBTs, supply faster switching speeds, reduced losses, and can stand up to better current densities, making them optimal for applications like electrical vehicle billing stations and photovoltaic inverters. On The Other Hand, SiC Schottky diodes are commonly made use of in high-frequency rectifier circuits as a result of their absolutely no reverse healing features, effectively reducing electromagnetic interference and energy loss.

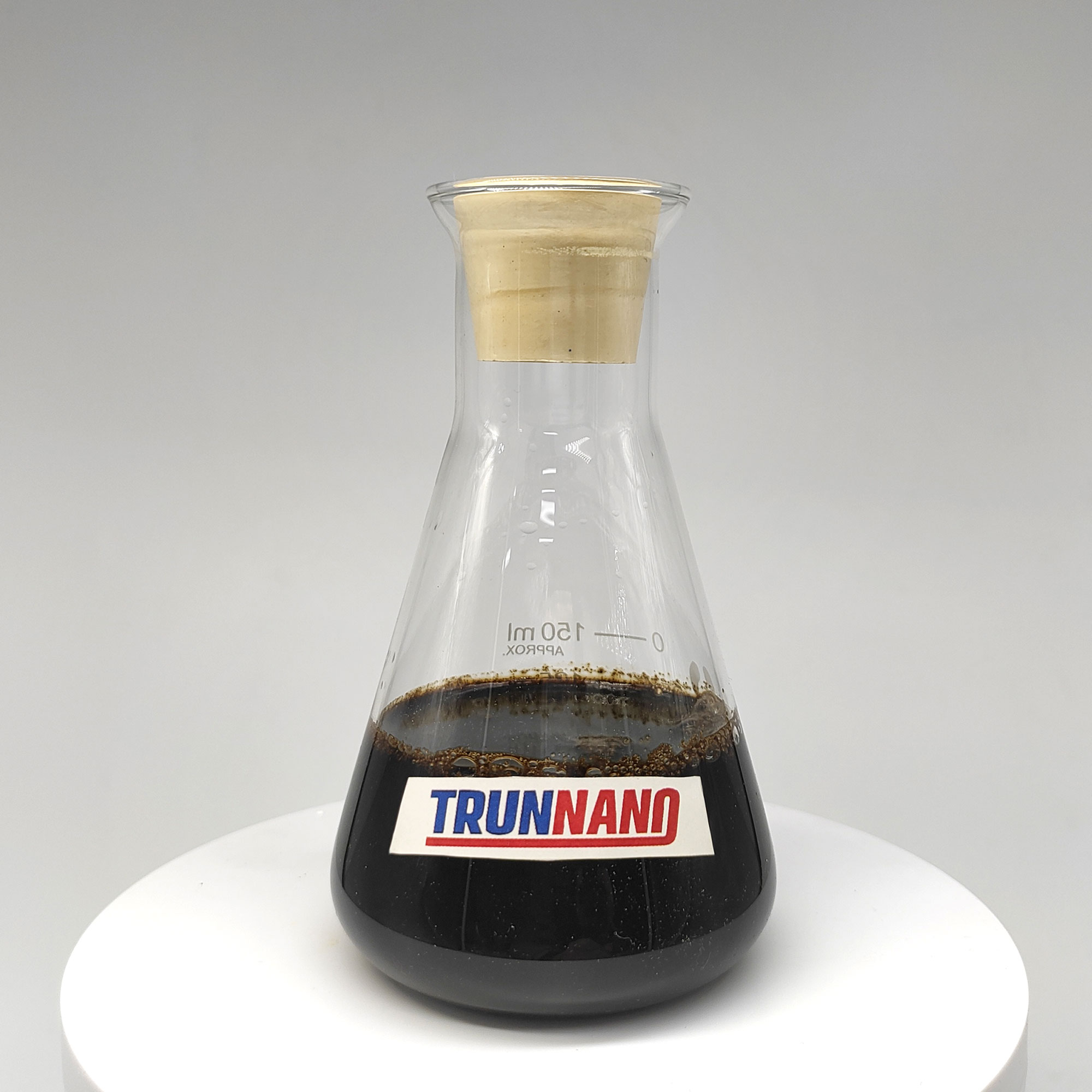

(Silicon Carbide Powder)

Given that the successful preparation of top quality single-crystal silicon carbide substratums in the early 1980s, scientists have actually gotten rid of many key technological difficulties, such as premium single-crystal growth, defect control, epitaxial layer deposition, and processing techniques, driving the growth of the SiC industry. Globally, several business focusing on SiC material and device R&D have actually arised, consisting of Cree Inc. from the United State, Rohm Co., Ltd. from Japan, and Infineon Technologies AG from Germany. These companies not just master sophisticated manufacturing innovations and patents yet also actively take part in standard-setting and market promotion activities, promoting the continual improvement and development of the entire commercial chain. In China, the government places substantial emphasis on the innovative abilities of the semiconductor sector, introducing a series of encouraging plans to motivate enterprises and research organizations to raise investment in arising fields like SiC. By the end of 2023, China’s SiC market had actually exceeded a range of 10 billion yuan, with expectations of ongoing fast development in the coming years.

Silicon carbide showcases its technical advantages with various application situations. In the brand-new power car sector, Tesla’s Design 3 was the very first to embrace complete SiC components rather than conventional silicon-based IGBTs, improving inverter efficiency to 97%, improving velocity performance, reducing cooling system concern, and expanding driving range. For photovoltaic power generation systems, SiC inverters better adjust to complicated grid settings, showing more powerful anti-interference abilities and dynamic reaction speeds, especially mastering high-temperature problems. In terms of high-speed train traction power supply, the current Fuxing bullet trains include some SiC elements, attaining smoother and faster beginnings and slowdowns, boosting system reliability and upkeep ease. These application examples highlight the enormous potential of SiC in boosting performance, decreasing costs, and enhancing dependability.

()

In spite of the several advantages of SiC materials and tools, there are still obstacles in functional application and promo, such as price problems, standardization building and construction, and talent cultivation. To progressively overcome these obstacles, sector specialists believe it is required to innovate and strengthen participation for a brighter future continually. On the one hand, deepening essential research study, checking out new synthesis approaches, and boosting existing procedures are essential to continually minimize manufacturing prices. On the other hand, establishing and improving sector standards is essential for promoting worked with development amongst upstream and downstream ventures and building a healthy environment. Additionally, colleges and research study institutes need to boost academic financial investments to cultivate more top notch specialized abilities.

In summary, silicon carbide, as a highly appealing semiconductor material, is progressively transforming different elements of our lives– from brand-new energy automobiles to clever grids, from high-speed trains to industrial automation. Its existence is ubiquitous. With continuous technical maturation and excellence, SiC is anticipated to play an irreplaceable role in extra areas, bringing more benefit and advantages to society in the coming years.

TRUNNANO is a supplier of Silicon Carbide with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about Silicon Carbide, please feel free to contact us and send an inquiry(sales8@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us